At Advance Flooring, we embrace the circular economy. We use recycled materials wherever possible in order to reduce our carbon footprint, while simultaneously sustaining the quality, efficiency and durability of our products.

Energy savings from recycling aluminium

After iron, aluminium is the second most used metal on earth. It is also one of the most recycled, with an estimated 75% of all aluminium ever produced still in use today.

Recycling aluminium is a far more environmentally friendly process than producing new aluminium from raw materials (which is known as primary production). In fact, recycling requires only about 5% of the energy required for primary production.

Aluminium for flooring products

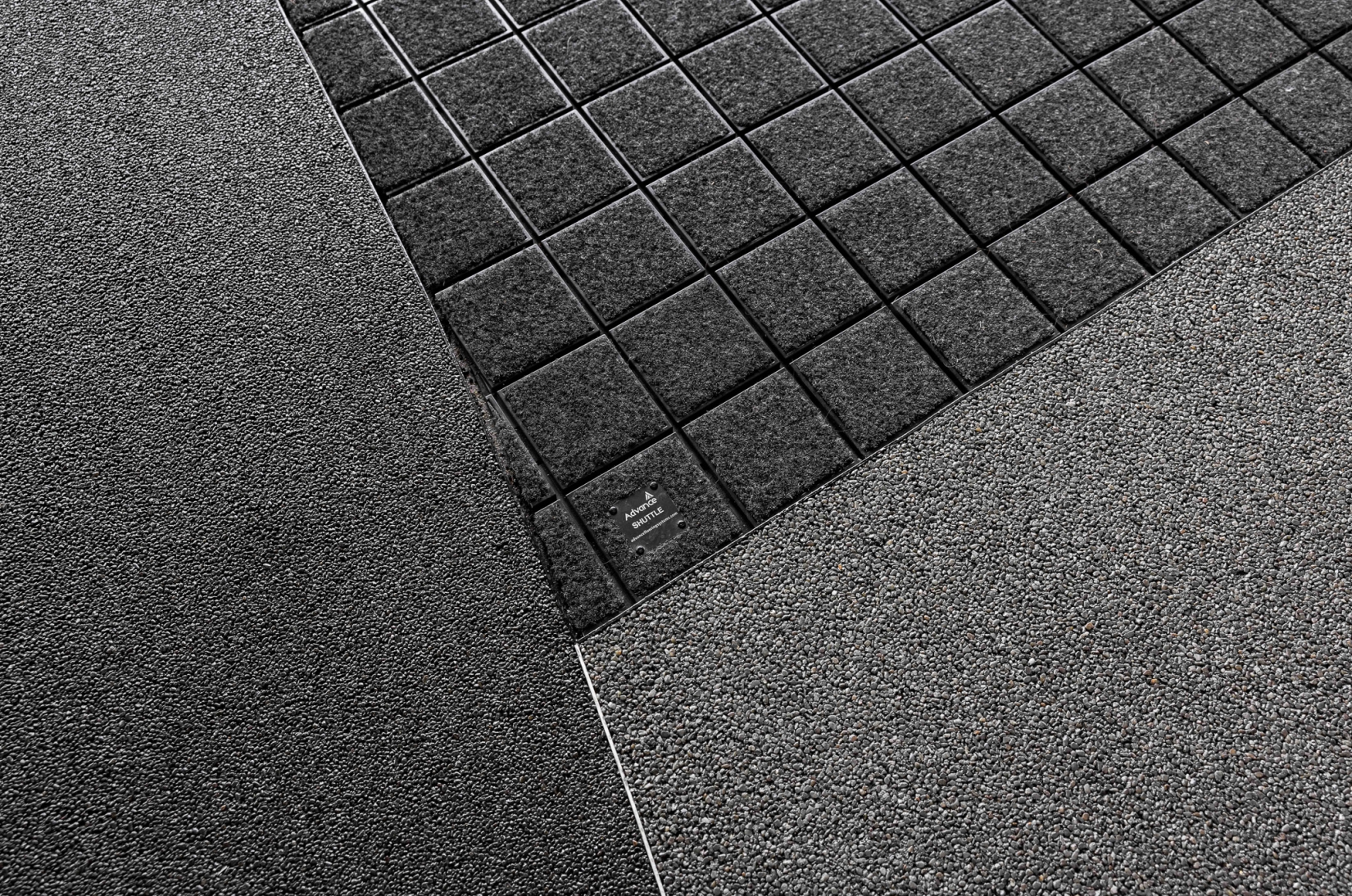

As much as possible, Advance Flooring’s entrance matting systems are constructed using recycled aluminium. Additionally, the polyamide inserts in Shuttle, as in many of our systems, are made from Econyl® regenerated nylon, which is produced from recycled fishing nets and can be recycled over and over again.

While the energy savings through recycling aluminium are substantial, there are still carbon emissions associated with the process. These emissions come from a number of sources, including the energy required to power the furnaces used in the melting process, as well as the transportation of the aluminium to and from recycling facilities. And since both these factors can vary widely, so can the carbon footprint of the recycled metal.

To help reduce our carbon footprint, the aluminium used in our Shuttle entrance matting system is cast from recycled aluminium in Whanganui using highly energy-efficient processes from a factory that is newly Global GreenTag certified. Our other entry matting systems are made from profiles extruded in Hamilton. The connecting systems are produced locally in Onehunga, Auckland, which also helps reduce transport miles.

Completing the cycle

Even factoring in the carbon emissions associated with recycling aluminium, it is still a more sustainable option than primary production. In addition to the energy savings, recycling aluminium also helps to conserve natural resources and reduce waste.

Wherever possible, the Advance Flooring products that use recycled aluminium are constructed using sustainable practices and designed to provide many years of use, even under heavy traffic. Once they have reached the end of their useful life, the component parts can themselves be recycled, further reducing the carbon load on the atmosphere and contributing to a better future for the planet.