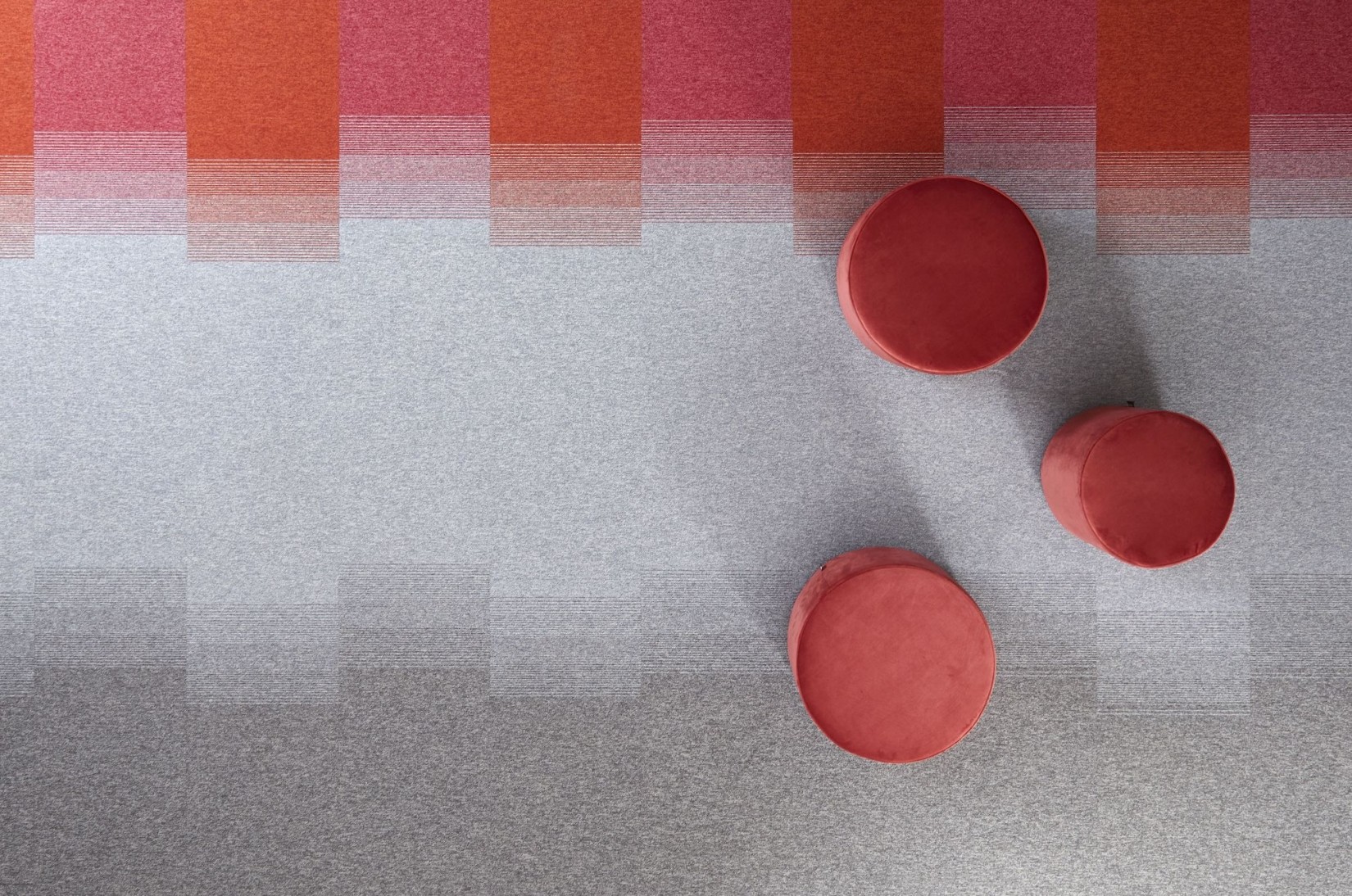

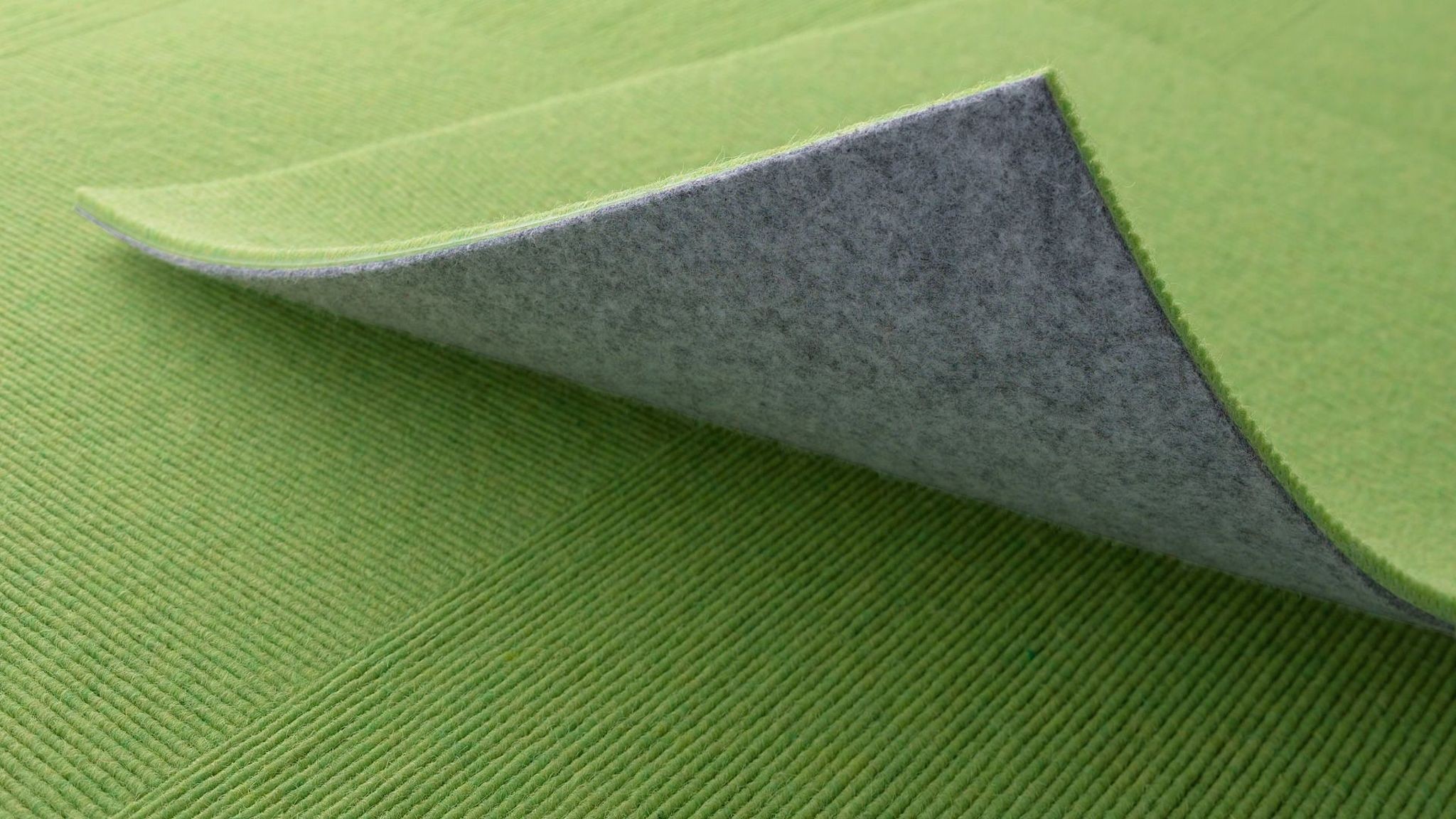

Product circularity

For both our own products and the trusted brands we partner with, we prioritise recognised environmental certifications and circular manufacturing processes. We approach every decision through the lens of cradle-to-cradle manufacturing—from thoughtful sourcing and material stewardship to designing with a circular economy in mind.

As we evolve our collections, decisions are guided by four key pillars: the use of renewable, recyclable, and non-toxic materials; systems that support take-back, disassembly and active recycling or reuse; energy efficiency; and production methods that minimise waste both in the factory and on-site.

Our newest product launch is Kinetex® modular carpet by J+J, made from recycled PET and fully recyclable in Aotearoa. Each tile contains the equivalent of 27 plastic bottles and is composed of 47% post-consumer recycled content. At the end of its long life, Kinetex can be returned to us to be recycled into insulation, soundproofing and packaging materials. It will come as no surprise that Kinetex is carbon neutral too.